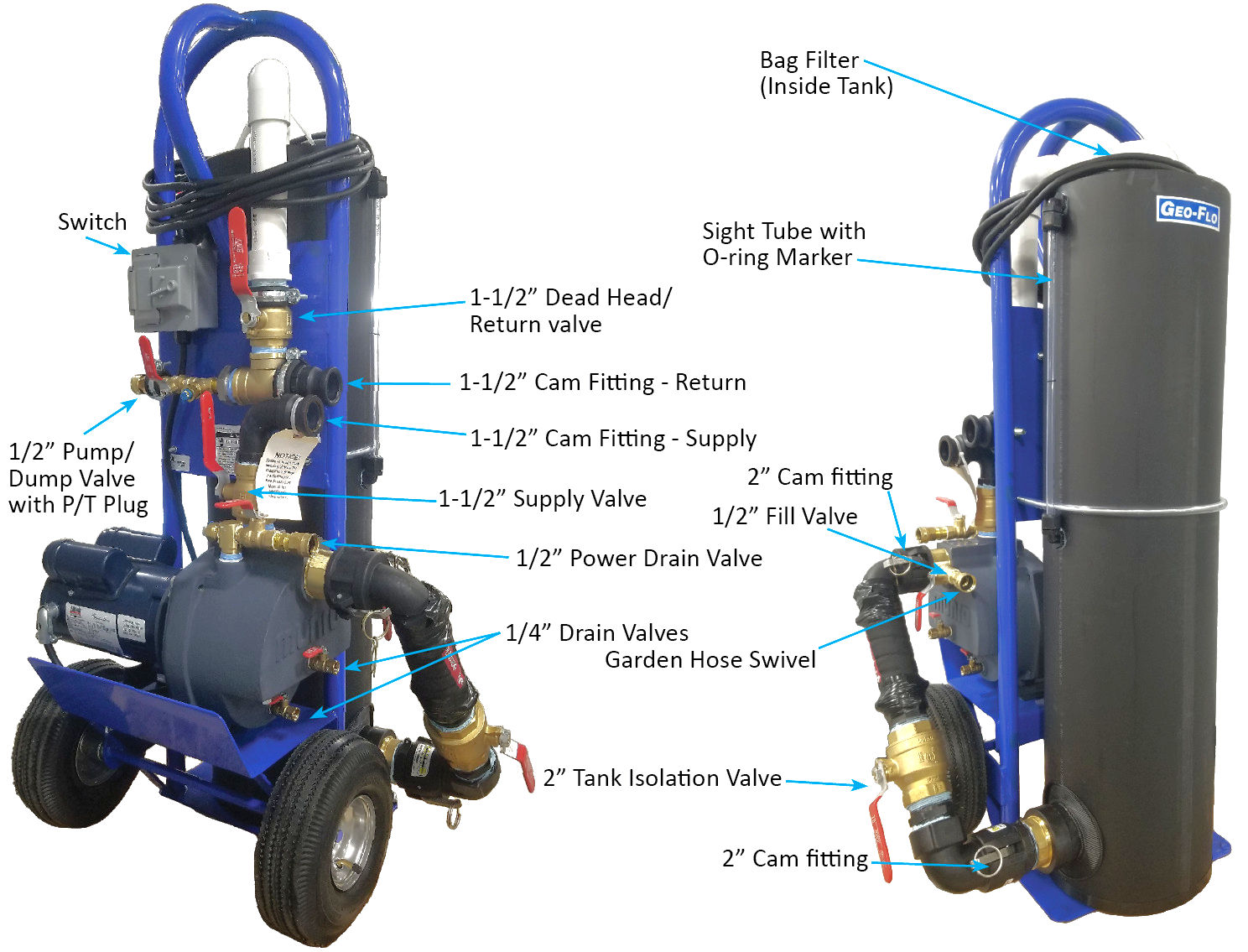

The Geo-Flo Flush Cart is the professional’s choice to purge air and flush debris from residential and light commercial geothermal ground loops. The flush cart has also been used to purge hydronic heating systems and flush heat exchangers in data centers as well as commerical and industrial buildings. Our Flush Cart includes all the important features required to safely flush and purge a ground loop heat exchanger including power flushing, power draining, pump and dump, and debris filtering. Its compact design utilizes standard components which allows for easy field service. The 1.5 HP self-priming 115V pump is mounted above the cart’s axle providing a well balanced system that is easy to maneuver. The Geo-Flo flush cart is the industry’s only ETL listed flush cart (to UL standard 778).

Features:

- Tank: 10” Diameter, 13 gallon capacity

- Hand Truck: P-Handle, powder-coated steel

- Tires: 10” Pneumatic

- ETL safety listed (to UL standard 778)

- Wiring: 20’ 12/3 SJO cord with 15 Amp male plug

- Power Switch: Weatherproof switch box with 20 Amp GFCI protected switch

- Filter: Removable/reusable, 31″ long, 100 micron, 90 GPM max. (standard); optional 1 micron add-on (P/N 3832)

- Power Flush Valve: Brass, 2” Full port

- Dead-Head Valve: Brass, 1.5” Full port

- Hose connections: 1.5” CAM male quick-connect

- Power Drain Valve: Brass, ½” Full port with garden hose swivel connection

- Pump & Dump Valve: Brass, ½” Full port with garden hose swivel connection

- Fill Valve: Brass, ½” Full port with garden hose swivel connection

- Pump Case Drain Port Valves:(2) ¼”, Brass

- PT Port: Located on discharge side of pump; allows pressure measurement

- Pump/Tank Connection: 2” flexible wire reinforced hose

- Sight tube: Flexible with O-ring; allows fluid level monitoring during dead-head operation to ensure air is completely purged from system

- Hose Assemblies: (2) 1-1/2″ ID flexible PVC hose with rigid PVC helix. 1-1/2″ cam female flush cart connections and 1-1/4″ ball valves with 1″ cam female field connections. NOTE: 1″ cam male adapters to flow center or loop purge valves are not included (see table below for options).

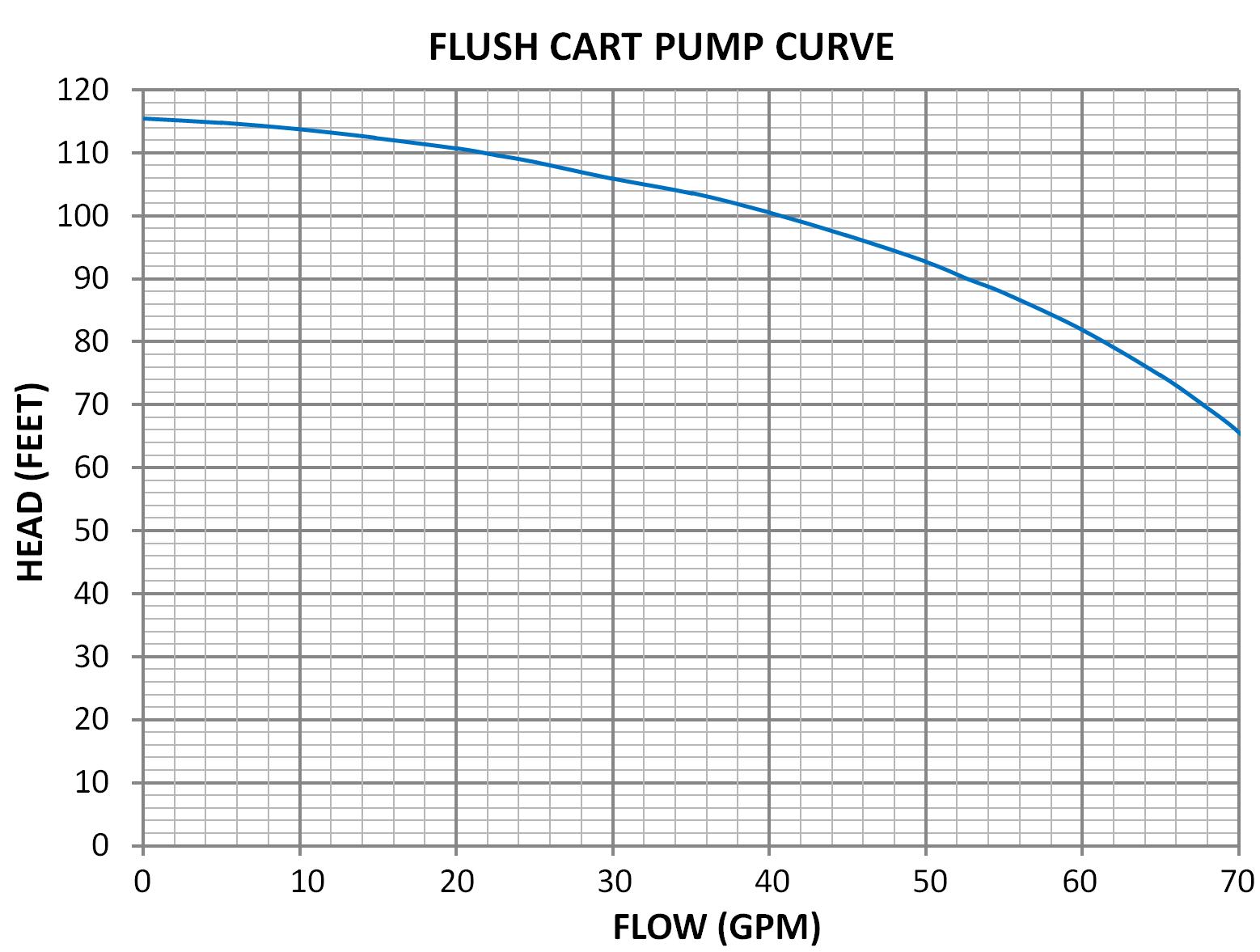

NOTE: Max flow rate = 70 GPM. Pump discharge pressure must be no less than 25.5 PSIG to ensure that the pump is within the allowable operating range (70 GPM max). Running at a pressure less than this will result in the motor over-amping and may result the motor tripping. The motor has built in thermal overload which provides some protection. If the pump shuts off during operation, allow the motor to cool. Before restarting, turn the 1-1/2″ supply valve approximately 2/3s of the way closed. Restart the pump and slowly open the supply valve while monitoring the discharge pressure until the necessary flow rate is achieved.

Additional information

| Description | Flush Cart w/ 10ft. hoses, 1" CAM fittings (loop side) & 1-1/4" ball valves, (2) 10ft hoses, 1" CAM fittings (loop side), 1-1/4" ball valves, (2) 10ft Black reinforced RUBBER hose, 1" CAM fittings (loop side), 1-1/4" ball valve, (2) 20ft hoses, 1-1/2" CAM fittings (loop side), & 1-1/2” CAM M X M coupler, 1 micron Filter Bag, 100 micron Filter Bag |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.